Bill Of Materials

Summary

Bill of Materials will allow you to:

- Compose kitted Products (Kit-types) that are made from a combination of component Products to create the result Product

- Optimize quantity Products (Quantity-types) by allowing Cases of a Product to be stocked but still allow the Singles to be ordered; which in turn allows the Product to be shipped efficiently by allowing Cases and Singles to be used to fulfill the Order

- Designate whether the Product should have its components picked on demand or if they should be assembled and put into stock first

- Create complex Product relations when several different Products can be used to complete the result Product

All BOMs are different, but they do follow a few general patterns:

- A "virtual" product that is composed of several products

- A "virtual" product that is composed of one product but is more than one quantity

- A product that is a case or pack containing multiple singles

- A product that is ordered as packs of the singles

Using these patterns you can create:

- A complex Product i.e.: a desk that comes in different desktop materials and leg finishes

- Products as different quantities i.e.: Products as different quantities i.e.: Peanut Butter as singles and as 4-packs while only keeping stock on the 4-pack

This article will be explaining how to work with BOMs and Kit-type BOMs. Quantity-type BOMs have extra changes that build on what a Kit-type BOM can do. The Quantity-types article will be dealing with specific differences when working with Quantity-type BOMs.

Permissions

Add these Role Resources to allow a user to:

- View BOM Grid — Catalog > Bill of Materials

- Change System Configs — System > Configuration > Bill of Materials

Preparing

Before creating a BOM be sure to first create the Products and any "virtual" Products that might be needed. A "virtual" Product is the result once all the components have been assembled. E.g.: "A desk with a Hardwood desktop and Black legs" which is composed of one "hardwood desktop", a box of "black legs" and one "bag of desk parts".

A Desk with variations that could have a "Laminate desktop" or "Hardwood desktop" option and the legs that come in black, white, and silver. These options mean a Desk would need six different "virtual" Products to cover each choice.

Creating a Bill of Material

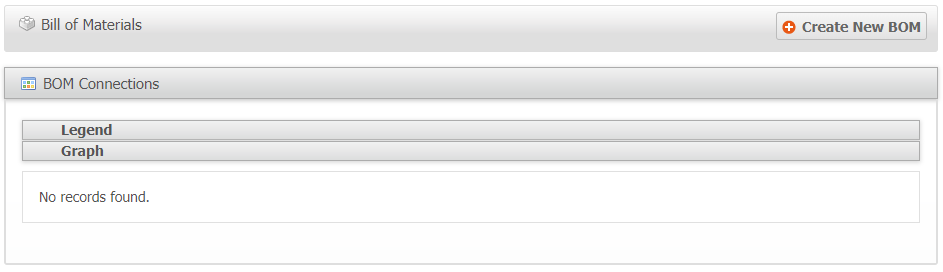

Creating a new BOM is done from a Product's view > Bill of Materials tab.

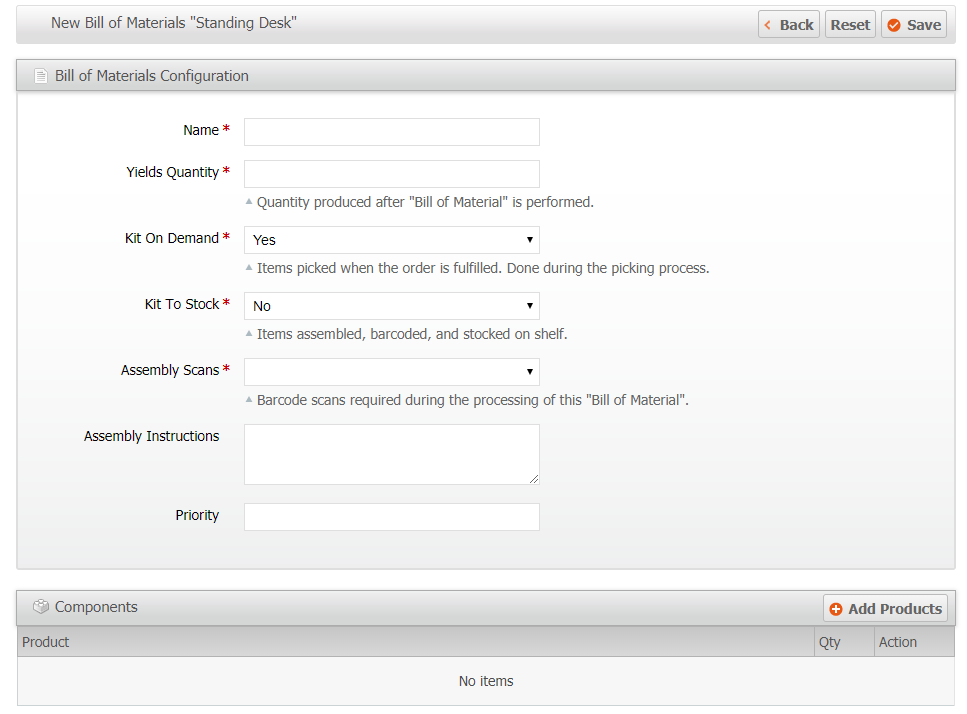

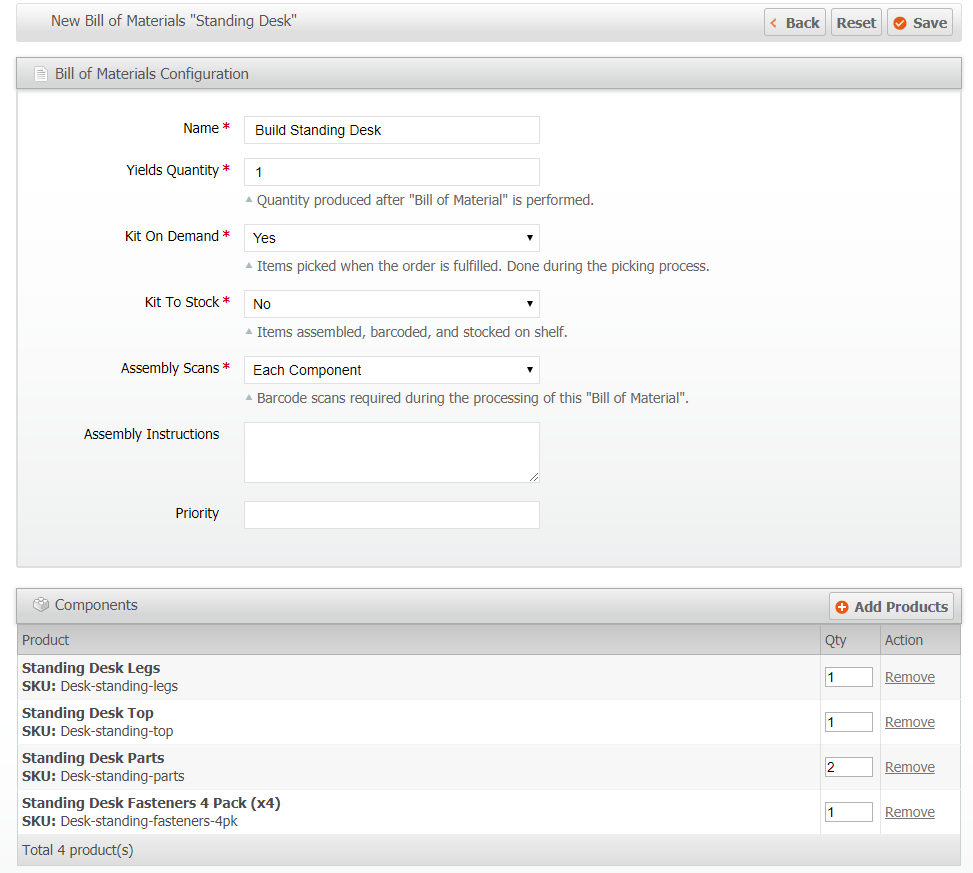

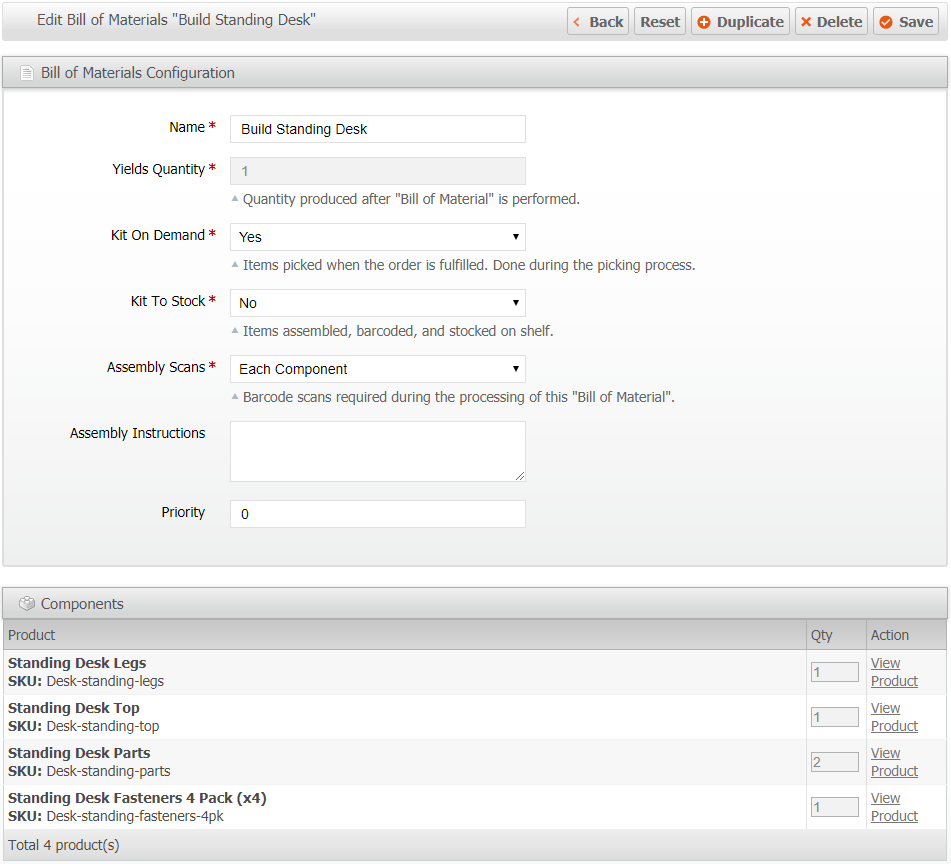

BOM Configuration

Name

The name of the BOM; it helps to be descriptive, to describe the relation, which helps when reading BOM graphs and looking at the info about a BOM. e.g.:

- Pack Crafting Kit

- Build Crafting Kit 2A

- Split Canned Air Case(24) into Singles

- Split Canned Air Case(24) into 6 packs of 4

- Build a 4 pack of Canned Air from Singles

- Pick Mini DC Motor Mfr. ACME Inc.

- Pick Type 130 Mini DC Motor Model: EK1894

- Make a 4 pack of Flashlights from Singles

Yields Quantity

The resulting quantity when this BOM is fulfilled; also determines if this is a Quantity-type. i.e.:

- Splitting a Case of 50 would yield 50 Singles — Yields Quantity: 50

- Kitting a Craft Kit — Yields Quantity:1

Defines what kind of BOM this will be:

- A Kit-type BOM will have a Yields Quantity of one

- A Quantity-type BOM will have a Yields Quantity that is greater than one

Kit On Demand

Determines if this BOM can be picked when an order is fulfilled.

- When set to Yes orders for this BOM Product will be picked as components to fulfill the order

- When set to No then orders for this Product must be pre-kitted with barcodes so that this Product has inventory in stock

Kit To Stock

Determines if this BOM can be pre-kitted by creating Work Orders to kit this BOM together.

Assembly Scans

Determines what scans are needed as each component is assembled. Used when assembling Work Order items.

- Each Component — Each component will be scanned as the BOM is kitted together

Assembly Instructions

User can provide instructions for assembling these particular components together during a Work Order.

Priority

The priority that this BOM will have in relation to other BOMs on this same Product. Zero is the default value. The larger the number the lower the priority will be. i.e. Use to prefer one manufacture's component over another when both can equally be used to fulfill the yielded BOM Product.

Adding Components

Components are the individual Products needed for this BOM to fulfill this Product. This can be as simple as adding one Product at one quantity or as complex as adding multiple Products with varying quantities.

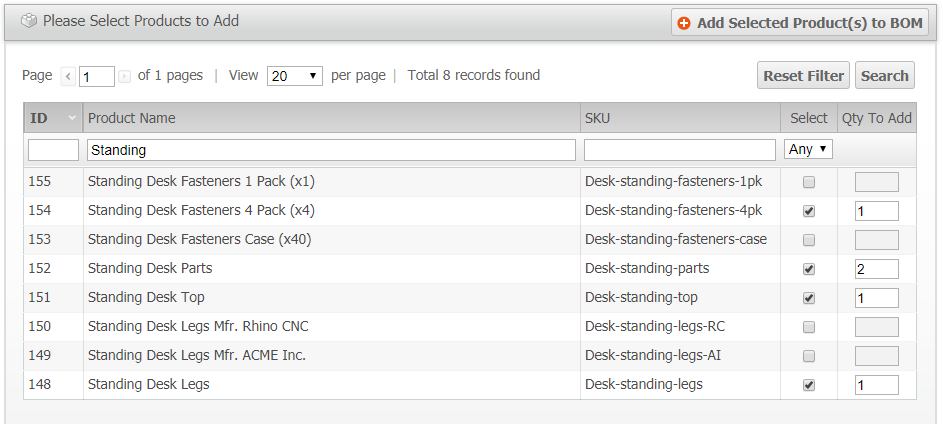

When adding components you will see a list of Products for this Merchant. From this list you can select the items and quantity needed for this BOM to fulfill this Product. Once a Product has been selected it can be added to the BOM.

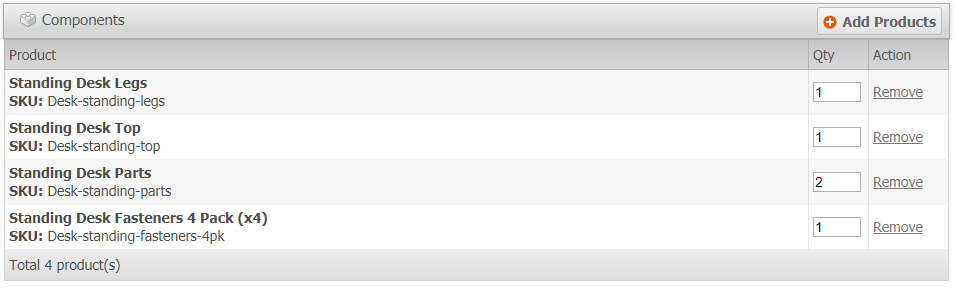

Once a Product has been added to the BOM, the Product(s) can be removed or have their quantity updated. Additional Products can still be added to the BOM.

Once the BOM is configured and the Components have been selected the BOM will be ready to save.

Editing a Bill of Material

A BOM can be edited from a Product's view > Bill of Materials tab and from Catalog > Bill of Materials grid.

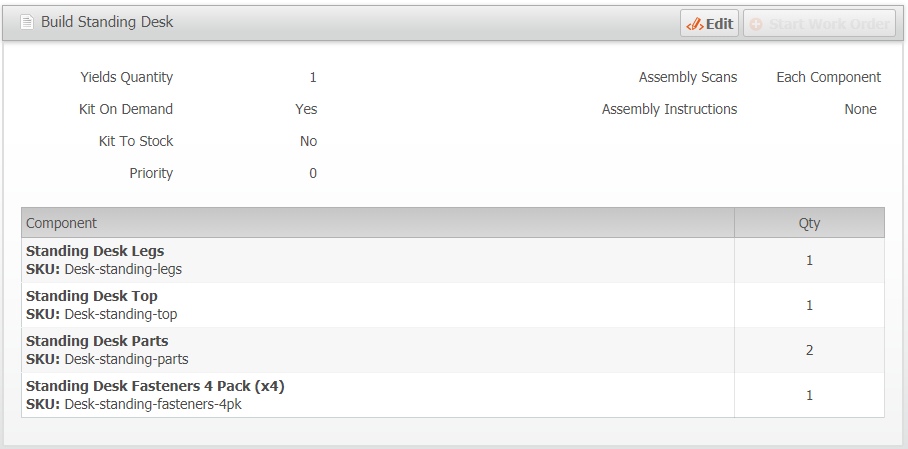

Editing a BOM will allow you to edit certain parts of the BOM configuration. The components section will now show you the quantity used and a link to go directly to the component Product.

Viewing Bill of Materials Details

A BOM can be viewed from a Product's view > Bill of Materials tab and from the Catalog > Bill of Materials grid.

Bill of Materials tab

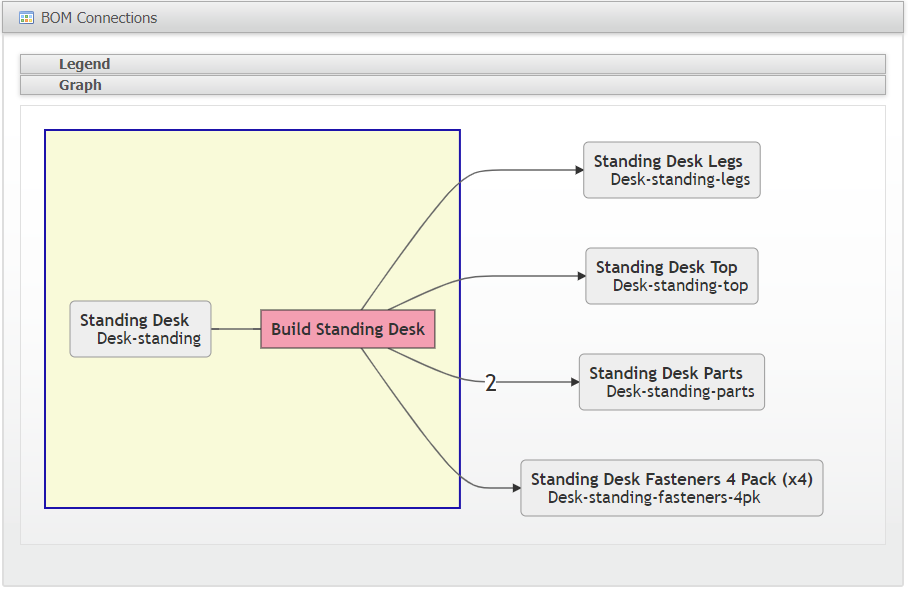

The Bill of Materials tab contains two sections. The first section is a graph and the second section displays the details of each BOM on the Product.

BOM Connections

Once a BOM has been created you will see a graph showing how the BOM relates to its components and any other BOMs using some of the same Products.

The Legend and Graph views can be expanded or collapsed by clicking on their respective headers.

A Product's BOMs

An information block is shown for each BOM on the Product. The info shows the details of the BOM's configuration settings and the components selected for the BOM.

Bill of Materials Grid

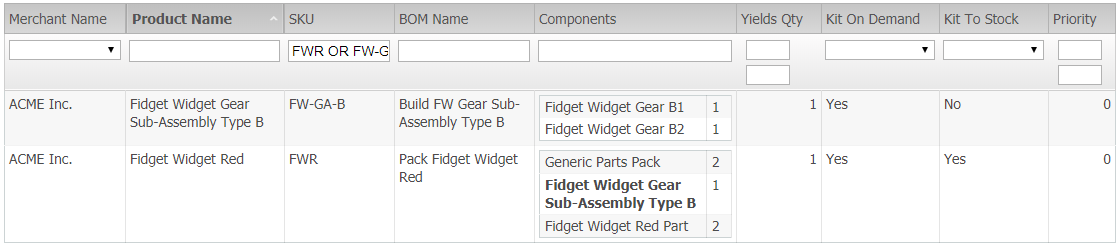

BOMs can also be viewed and exported from the Bill of Materials Grid. This grid is located at Catalog > Bill of Materials.

On this page you can view all the BOMs and filter and export BOMs as desired. When looking at the Components column if you see a product with bold lettering, that indicates that that Product also has a BOM.

Clicking on a BOM row will allow you to edit that BOM.

Using Bill of Materials

Kit-type BOMs won't change much of anything when working with Deliveries. However Quantity-type BOMs will change several aspects. You can read about the major differences when working with Quantity-type BOMs in the Quantity-types article.

The following is on how BOMs in general and Kit-types particularly behave within ShipStream.

Deliveries

Deliveries should be made for the components needed to fulfill or return the Product the BOM is on. Deliveries will behave like normal Deliveries.

Inventory

Since Kit-type BOMs are composed of their component Products, the Product with the BOM may often contain zero inventory. When a Product with the BOM is Ordered, the System will tell the user to Pick the component Products to fulfill the Order. Stock can be pre-kitted through Work Orders to allow a BOM Product to have stock. The Merchant could also deliver the Product already kitted and some delivered as components.

Orders

An Order for a Product with BOMs, when working out how to fulfill the order, will first look at the stock on the Product then at the BOMs. The BOMs will then be looked at from highest priority to lowest to find the best solution to fulfill this Product.

Batching & Picking

Batching and Picking Kit-type BOMs will work and look like normal Orders.

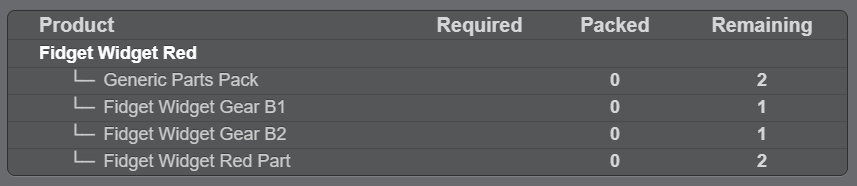

Packing

Packing a Kit-type BOM will show the Product ordered and the components will be indented underneath the ordered Product. It will look similar to a tree view.

Viewing BOM Information on

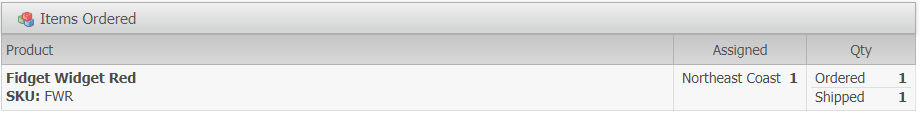

Orders

The items ordered will continue to show exactly what was ordered.

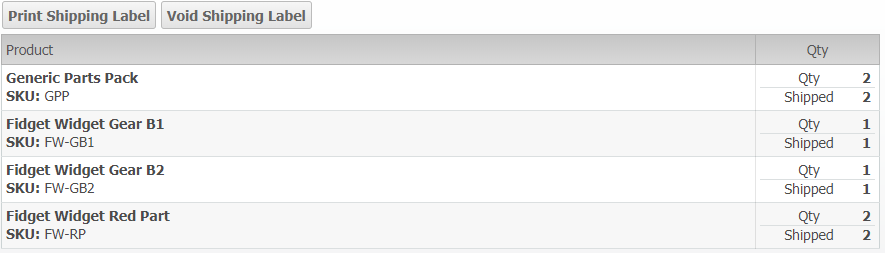

Shipments

Shipments will however, show the component Products that make up the Product with a BOM.

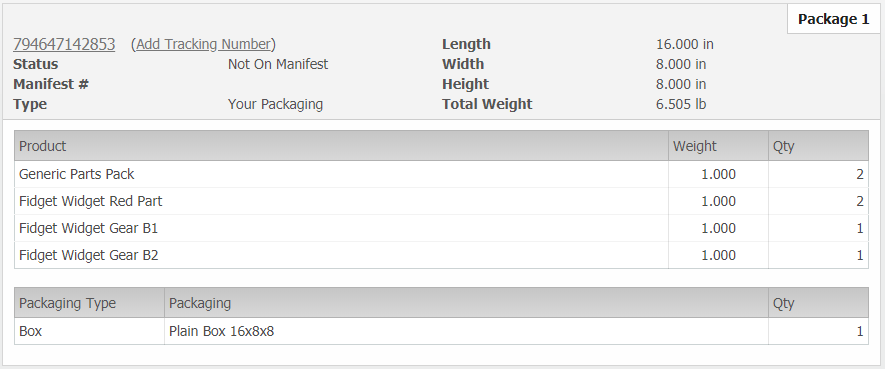

Packages

Packages will also only show what was scanned into the package, which are the component Products.

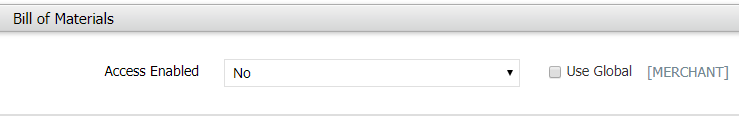

Merchants and BOMs

By default Merchants cannot create BOMs because of their complexity. If it is desired to give a Merchant permission, the settings can be found in System > Configuration. Select the Merchant's Scope then in the Clients > Catalog tab is the Bill of Material sections that allows the Merchants to create BOMs.